Crystallisation of Epoxy Casting Resin - How to Fix by Liz Hoyland!

Have you found your resin solid, cloudy or small white flakes in it? That means your resin has crystallised but all is not lost. Vista Art Resin Specialist and Forum Moderator (Vista Forum), Liz Hoyland has some information to help you out.

Resin is a super-cooled liquid. Meaning it stays liquid past its freezing point. But super-cooled liquids develop crystals at lower temperatures. Which if kept at lower temperatures for longer periods of time, or experience very low temperatures it occurs. There is a variety of reasons crystallisation can occur, some of those reasons being – temperature fluctuations and longer exposure to lower temperatures.

Products with a higher purity of resin and a lower viscosity like Vista are more sucestible to crystallisation, but all epoxy resins will experience this to differing degrees.

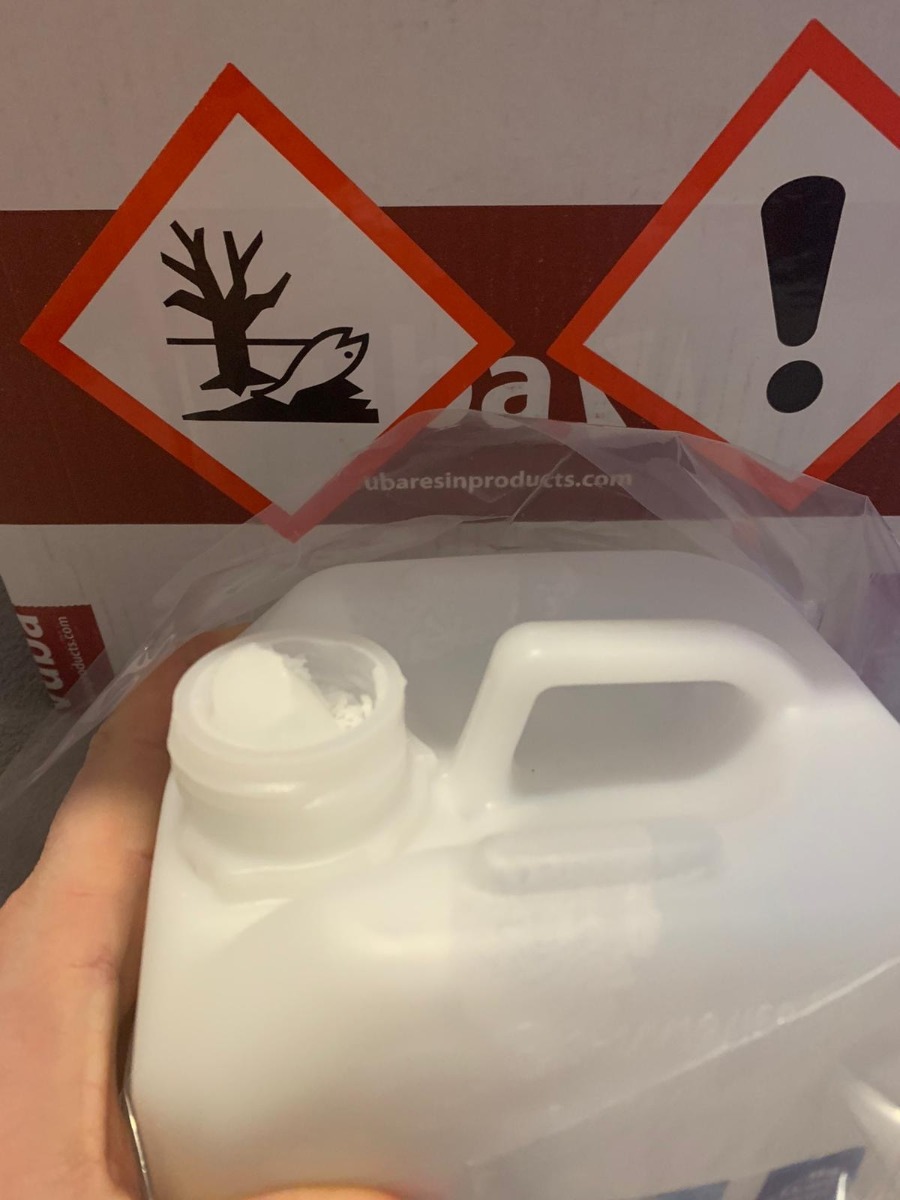

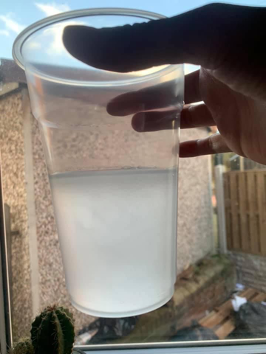

Sadly, crystallisation is unavoidable because it is a naturally occurring process, however it can easily be reversed with a moderate amount of heat. Which I will explain below. During very cold conditions, such as when in transport for delivery during winter. Being stored low down, on the flooring or even low shelving, also in areas that are susceptible to colder conditions. Part A of a 2-part epoxy resin will crystalise, this can vary from a few flakes of white floating in your cup/ a milky white appearance/ wall paper paste consistency up to finding your resin component A as a solid white block in the bottle, making it impossible to pour out.

If you find the part A is solid in the bottle/ is unable to be poured or you intend to use a larger amount/ all of it. You can create a water bath for the whole bottle. In this case it is likely you will need to top up with hot water as the water in the bath cools. If you're using a sink, just drain some water away. Using a bucket try to make sure its somewhere you can tip some out or into another container to avoid water all over. Leaving the lid on you can always swirl the resin in the bottle to help it mix.

If you notice after pouring your part A into your mixing cup there is anything from flakes to wallpaper paste consistency. Fill a bowl with warm water and sit your cup in the middle. Depending on how crystalised your resin is will depend how long you will need to wait/ keep an eye on it. Gently mixing the part A intermittently can help mix up to warmed and crystalised resin, speeding up the process slightly.

[Be careful not to get water splashed into your cup, or risk your cup tipping.]

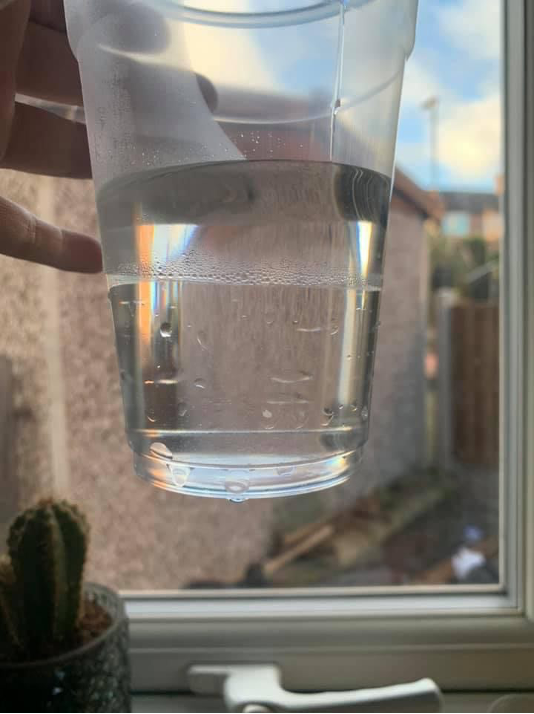

Once your resin is clear, you can easily mix in part B. Continue on to add your colours and enjoy making resin magic!

Images to show cloudy crystalised resin before and after being warmed in a water bath.

For future ease of use, you can try to combat this issue by storing your resin around 24 degrees or above, cleaning round your lids and keeping your tools clean, to avoid contamination.

Remember, it may be a very annoying issue to notice when your just about to go to work, but it is a naturally occurring process, in many 2-part resins. Using high quality resin, especially those that are low viscosity can play part in it. (So, don’t worry, its easily sorted and could be a good sign of the quality of your resin being used.)

Thank you for taking the time to read, I hope this helps give you clarity (pun intended). Happy resining!

Liz Hoyland

Art Resin Specialist & Forum Moderator