Mrs Hinch’s Farmhouse Makeover

Mrs Hinch took to her Instagram Story earlier this year to update her 4.6 million followers that a Resin Bound driveway was next on her home to-do list.

Well known for her tips and tricks for the home, Mrs Hinch has a devout following of home improvement aficionados, waiting for their next fix of @mrshinchhome inspiration.

Mrs Hinch chose Vuba Resin Products to bring her Resin driveway from a dream to a reality, benefiting from Vuba Approved Installers for a hassle-free install.

- All About That Base

Originally, Mrs Hinch planned to overlay her existing Tarmac, which is a relatively cost-effective way to transform your tired and old Tarmac.

However, finished Tarmac like other paving surfaces such as concrete and even block paving is not permeable. This means that when it rains, water sits on the surface and runs down to the nearest drain and into the waterway.

This kind of non-permeable surface may soon be a thing of the past with new Government Restrictions on the horizon, to ensure more paving surfaces are permeable, to protect our waterways from flooding. Read more here.

Left: Lucy our Sales Manager is a Lifelong fan of Mrs Hinch!

Right: Mrs Hinch is timing the mix for James from JMP Surfacing!

- Future-Proofing Your Driveway

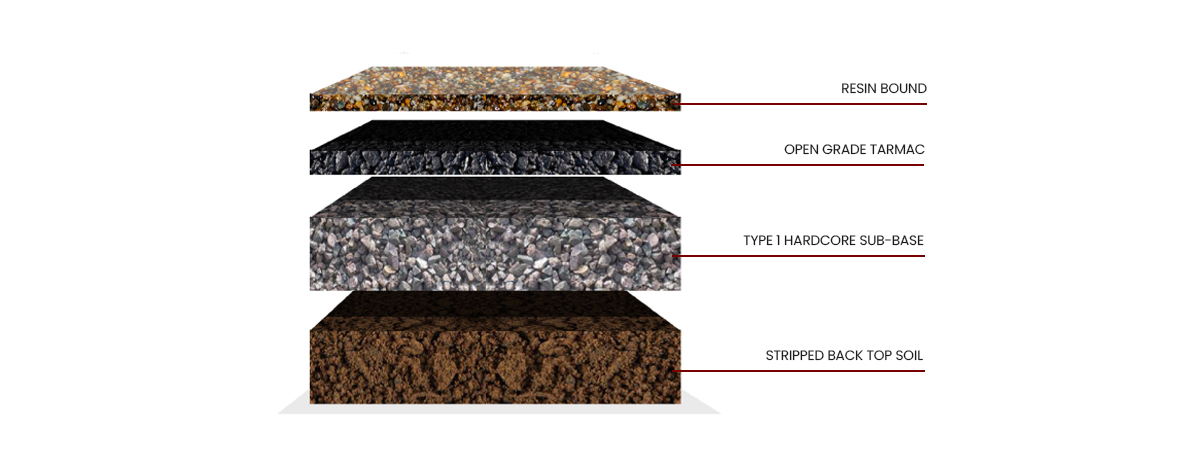

To create a permeable driveway surface with Resin Bound, it should be applied onto a new permeable base, such as “Open Grade Tarmac”. Open Grade Tarmac is 100% free draining and is the first layer before the impermeable top layer is then applied.

We’re essentially swapping an impermeable Tarmac layer, with a beautiful natural aggregate fully free draining resin bound surface!

Presented with these environmental credentials, Mrs Hinch opted to dig up her old Tarmac, followed by the laying of a new base, to create a completely free draining driveway.

Left: Vuba Resin Bound Binder - 7.5kg, UV Stable

Right: Here is a sledge from Hercules Tools in Action

- The Process

The first part of the process was to remove the existing Tarmac base, followed by the installation of Granite edging. Once the Tarmac is removed a new Type 1 Hardcore Sub-Base was laid to level the ground, providing a more stable base for the new Open Grade Tarmac, followed by the Resin Bound.

Approved Installer Danny Cooper managed the project on behalf of Vuba, and when it came to the laying day he was joined by “The Avengers” of our Approved Installer network to install the resin bound. ‘The Avengers’ consisted of Approved Installers; JMP Surfacing, Resway, A1 Resin Ltd and Jimmy Mac of MF Resin Driveways.

- Mrs Hinch’s Colour Choice

To compliment the Farmhouse exterior, Mrs Hinch chose the colour Pantheon with a border of Manhattan for the main driveway, the perfect contrasting combination for a classic but contemporary countryside aesthetic.

- A Resin Bound Driveway Just In Time For Dinner*

Resin Bound is designed to be entirely seamless and is always recommended to be laid in one phase. This whole project was laid in just one day, which is just one of the many benefits of this type of surfacing.

*A Resin Bound Driveway Just In Time For Tea (If you’re Northern)

We had a lovely day working with Mrs Hinch, and we couldn’t have been happier with how this project turned out.

Left: Great progress from Jimmy Mac, one of our Approved Installers

Right: Lucy showing the guys how it’s done!